Furnace Motor Installation Photos

Welcome to our 1,625 R.P.M. Motor Installation Page.

We will be showing you some pictures of a recent 1/2 Horsepower / 1,075 R.P.M. motor that we changed to a 3/4 Horsepower 1,625 R.P.M motor, capacitor and new

Universal Belly Band Motor Mount Bracket, to increase the air flow to the top floor for a client in our area. The furnace in the photos is a Goodman 90%

up flow furnace.

FIRST, SHUT THE MAIN POWER TO THE FURNACE, OFF AT THE BREAKER PANEL AND THE SERVICE SWITCH BY THE FURNACE ITSELF!

|

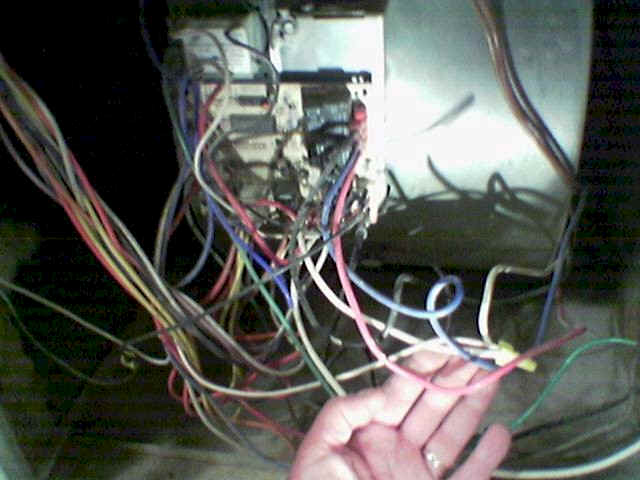

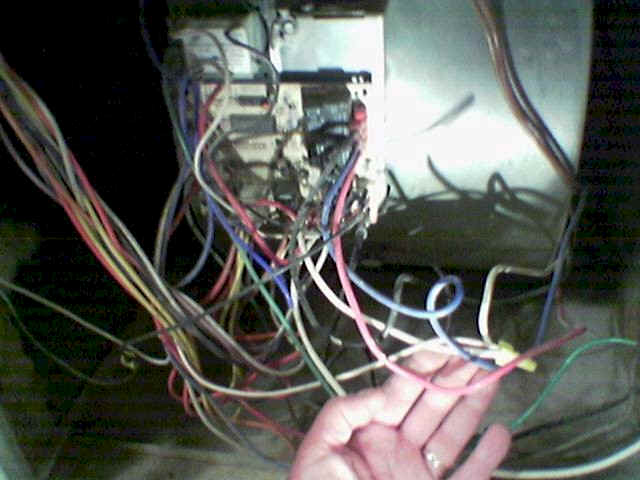

Here is a shot of the blower assembly complete with the furnace printed circuit board mounted on the front of the blower. Note the mess of wires! The

circuit board will have to be removed and HOPEFULLY there will be enough slack in the wires so that we can tie up the board and it's related wires high

enough to slip the blower out of the furnace. If this can't be done we will have to label each wire CAREFULLY so that we can remove all

the wires for the blower to be able to come out. We hope that won't be necessary! It would be wise to label the wires any way since wires have a nasty habit

of coming off the board and then you will have to read a wiring diagram ( if you have one and are capable of reading it ). |

|

Here we are removing the (2) screws that hold the blower in the furnace. Your installation may be different than this, but there will be some way that the blower is being held up. |

|

Now, the blower has been dropped down in the furnace. |

|

(2) screws are removed and the circuit board is off of our blower. |

|

We did manage to slip the blower out of the furnace and below is a shot of the old motor and it's bracket. This existing motor uses a bracket that is welded

to the motor itself. This will mean using a new universal belly band bracket on our new motor as well as a matching capacitor. We are removing the holding bolts

from the bracket, when these are out, we will flip the blower over and remove the set screw from the hub and shaft. |

|

Here is a shot of us removing the set screw. If we are lucky, the old motor should now drop out of the blower wheel! If it doesn't, we will have to drive the

motor out of the wheel with a brass drift and a hammer with the help of some WD 40. |

|

Here is the blower assembly in it's entirety. |

|

Here is the new motor and capacitor that we will be installing. |

|

We have got the old motor out on the floor, note the welded bracket. |

|

Here we are checking the new bracket to see if it will line up with the original bolt holes. In our case it does, if it didn't we would have to drill new holes

once we centered the wheel and motor in the housing. This centering is VERY important as the wheel may rub on the housing or vibrate if it is off center by very much! |

|

Here we have installed our new motor and bracket. Our belly band brackets come with heavy rubber grommets which run much quieter than the original motor brackets.

Please be sure to attach the green ground wire to a metal screw on the blower for safety. |

|

Now flip the whole assembly over, be sure the wheel is centered in all directions, be sure the set screw is tightened down on the flat spot on the motor shaft

and NOT the round part of the shaft! Once tight, give the wheel a spin and make sure it doesn't hit any where. Worth mentioning is, if the studs that come on the

motor are interfering they can be cut off if they aren't needed for mounting the motor. |

Now re install the blower assembly, install the new capacitor, give the wheel another spin when it is actually in the furnace to be sure it still is not rubbing anywhere.

If the rotation of the wheel is wrong, our motors are electrically reversible by changing a couple of wires in a plastic modular plug (see instructions that come with the motor).

Turn the power back on and start the furnace or air conditioning to test.